What is the definition of a garbage compression truck ?

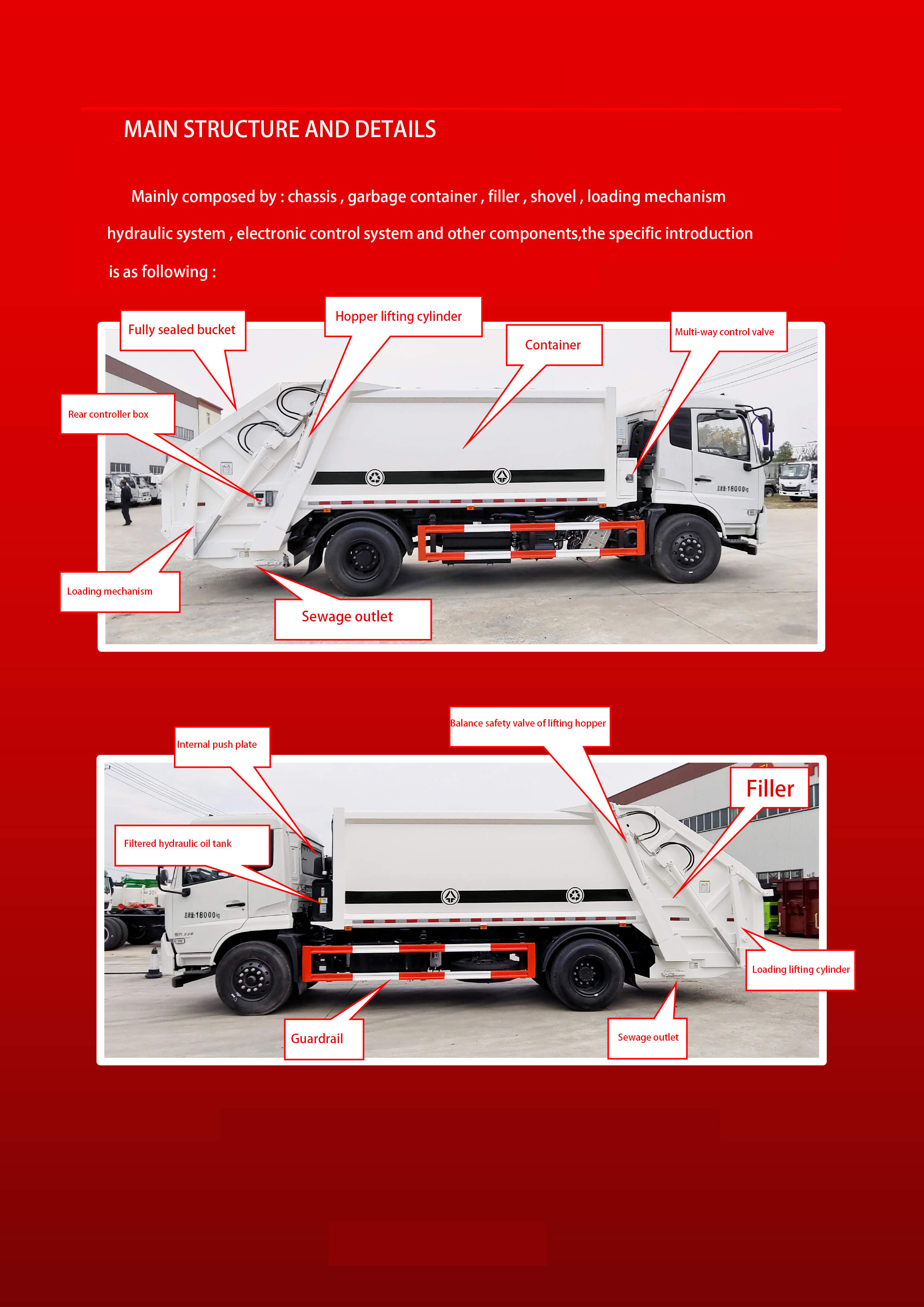

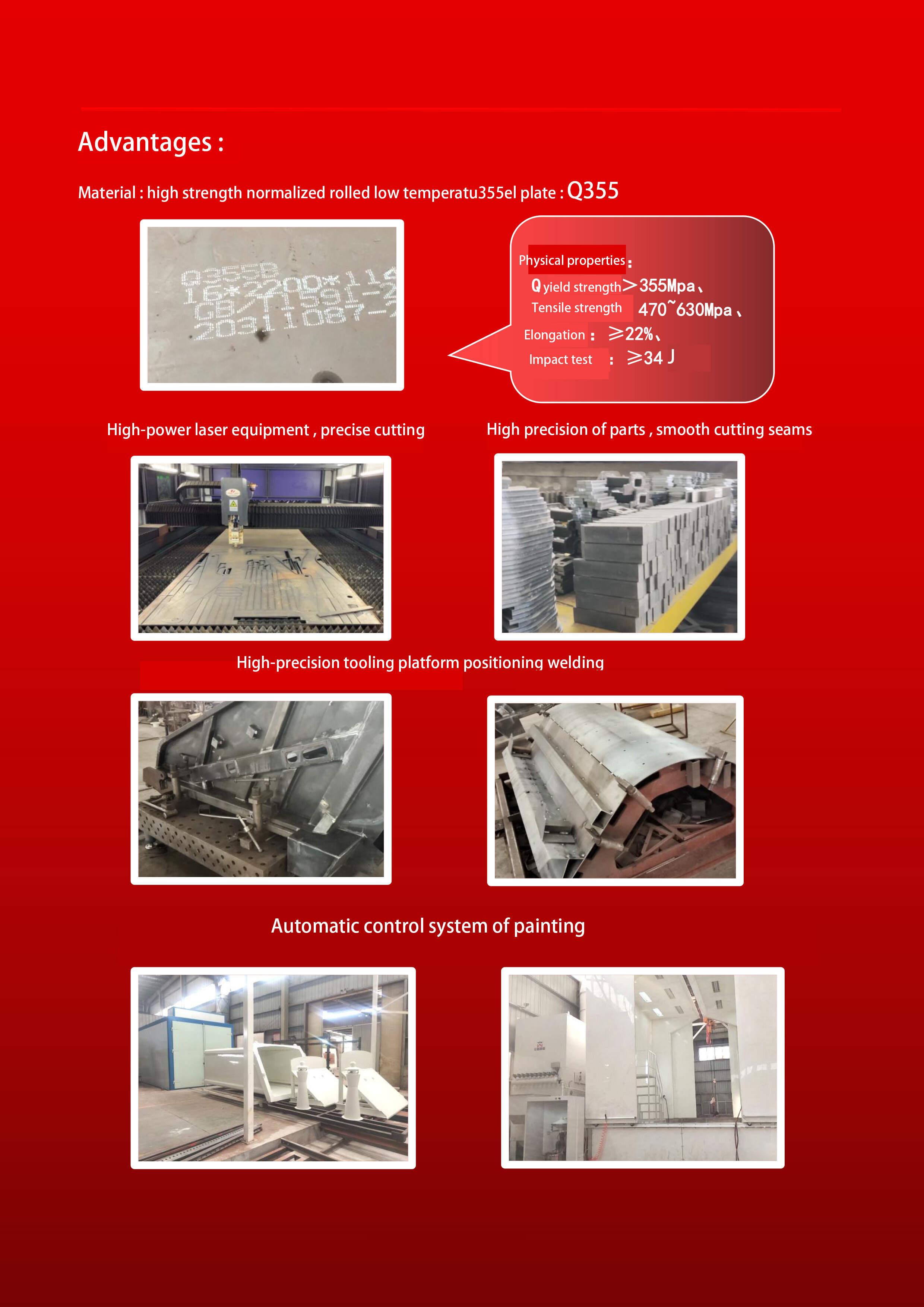

A garbage compression truck, often referred to as a compactor truck,refuse collection truck , compactor truck , waste compactor truck , trash compactor truck , sanitation truck , waste collection vehicle , garbage compactor vehicle , rubbish truck , dustbin lorry , refuse truck etc .which use digital design, high-power laser cutting, and robotic welding ensure high precision and zero errors. The structural components of the whole vehicle are independently molded, with strong compatibility, facilitating maintenance and upgrading. The first standardized production line for special sanitation vehicles in the country features unified standards, standardized procedures, and strict quality and inspection processes to ensure the stable and reliable quality of the products. The tank body adopts the coating process of electroscopes + electrostatic powder spraying, making the product's paint surface look beautiful and shiny, as well as durable. It will still look as shiny as new even after long-term use.

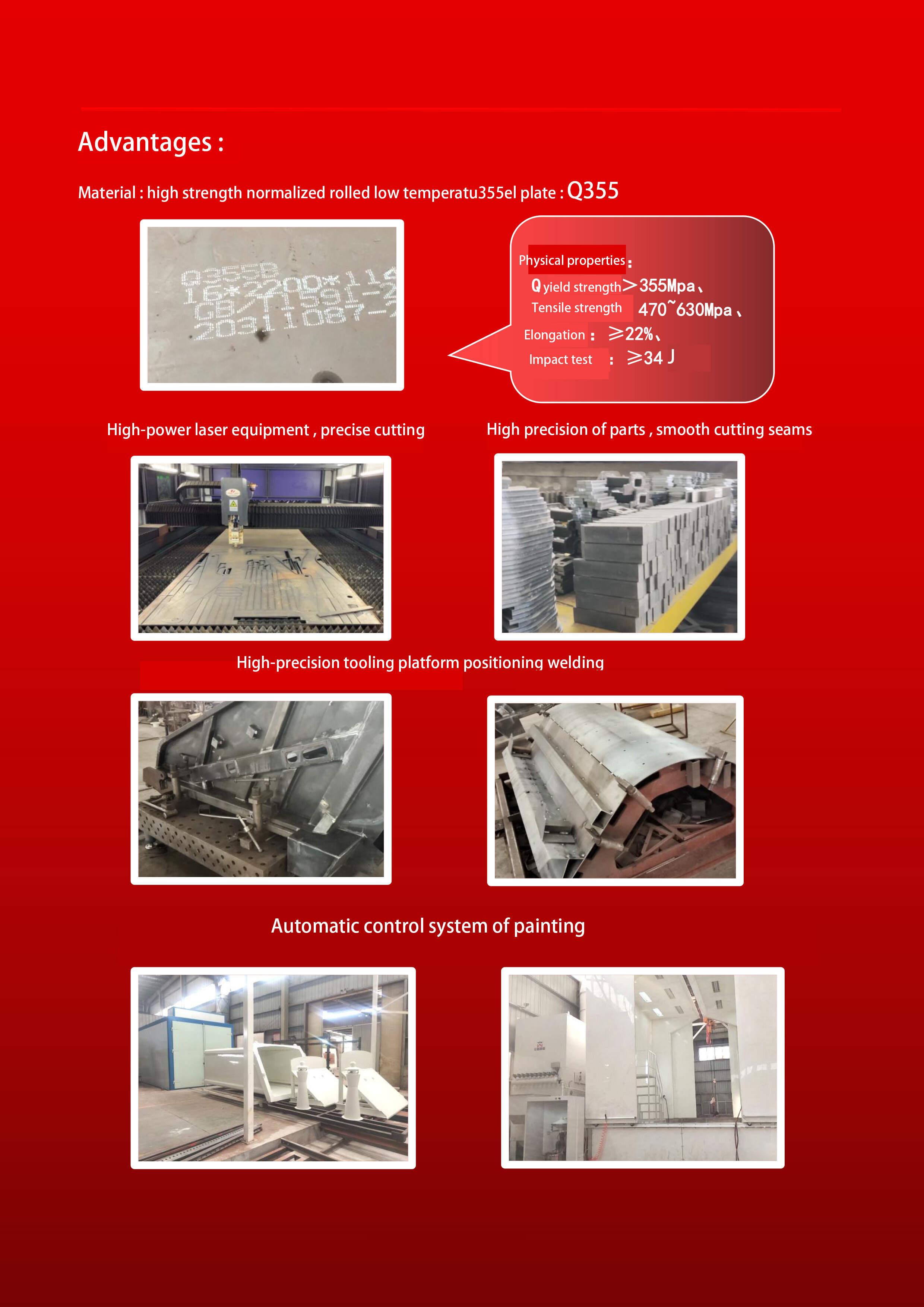

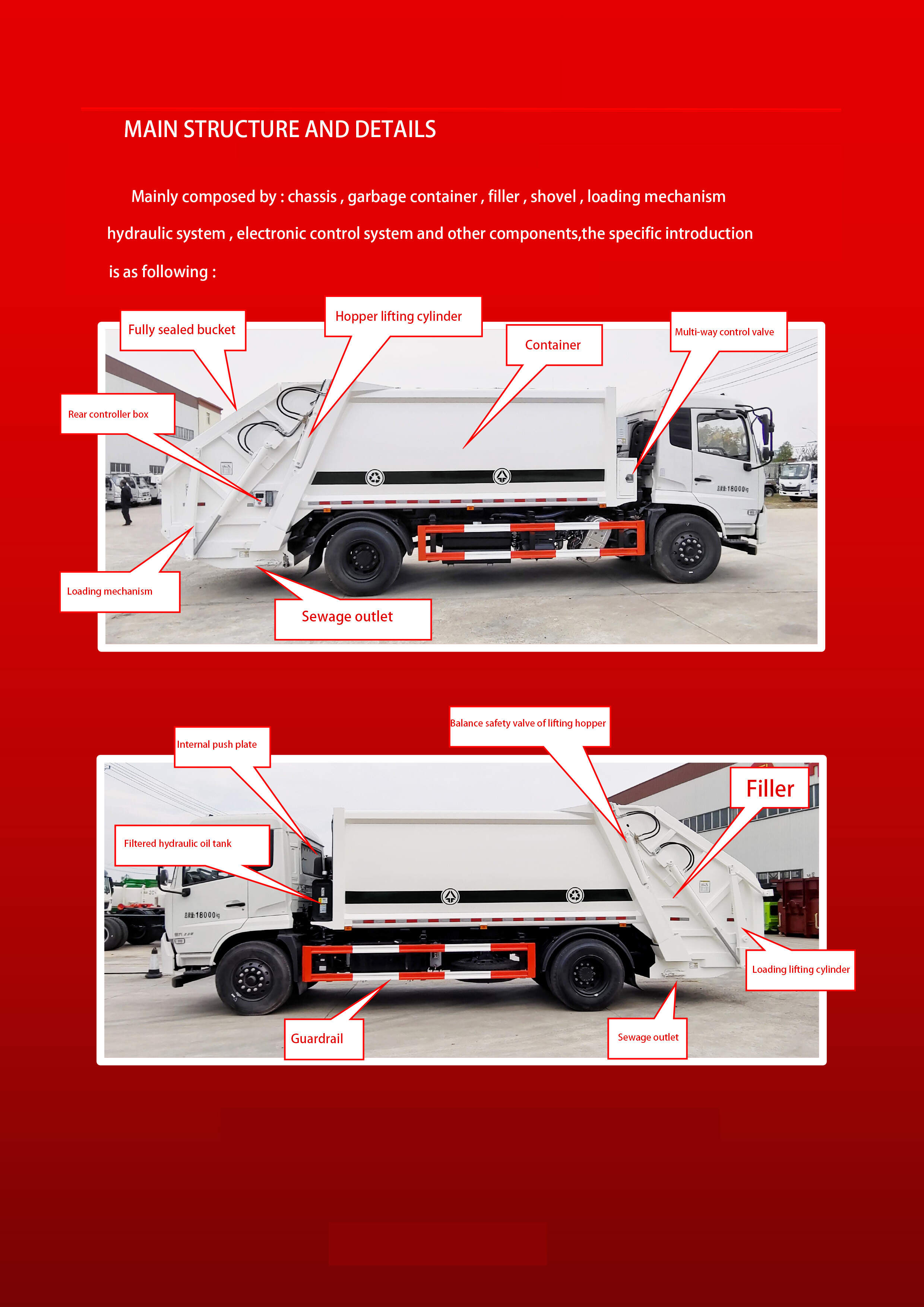

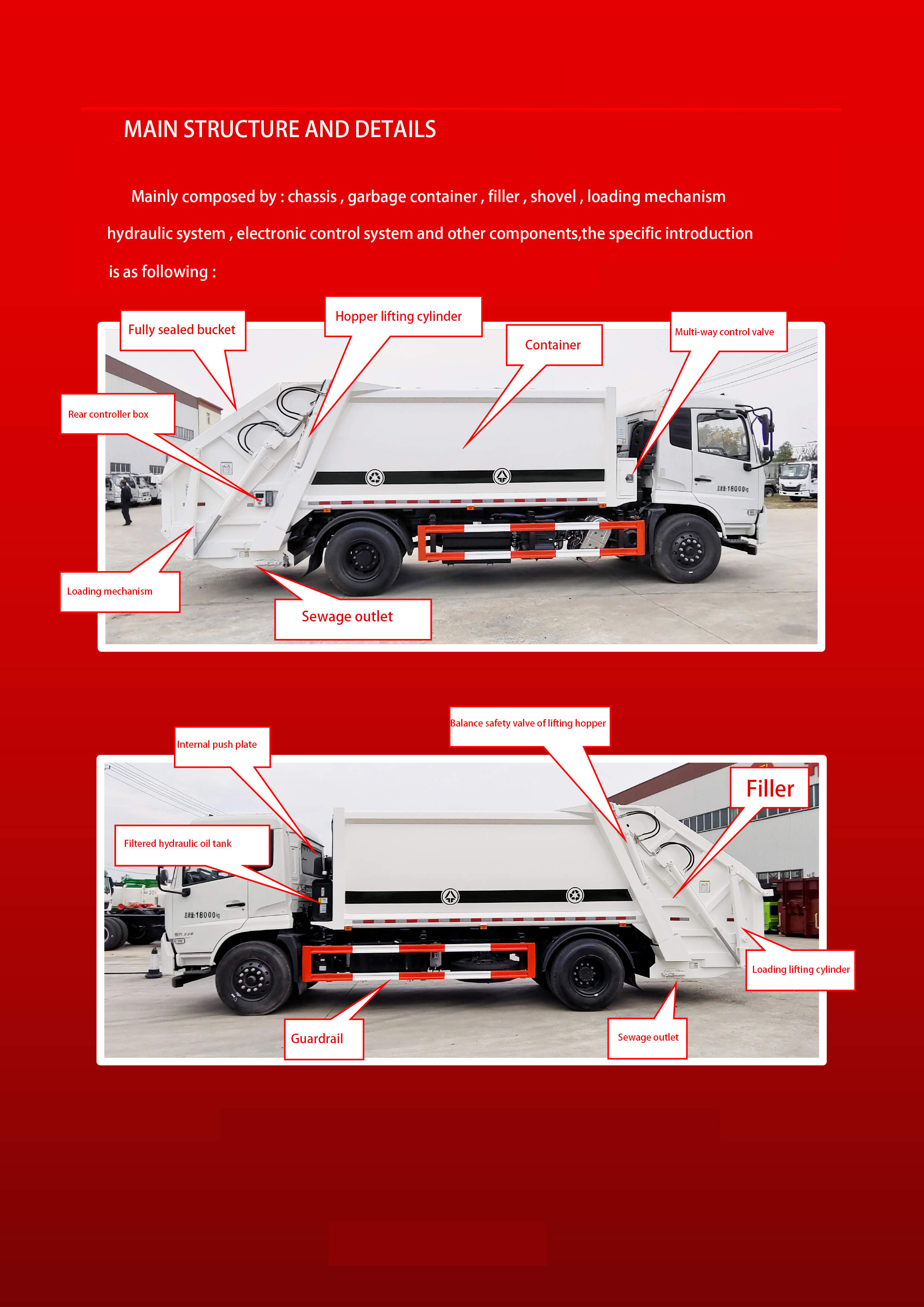

A Rubbish Truck is designed to collect, transport, and compact waste, making it more efficient to handle large volumes of trash. The truck works by using a hydraulic system to compress the garbage inside a sealed compartment, allowing more waste to be carried at once. Here’s a photo to show the parts of a trash compactor truck’ s parts :

Here's a breakdown of how it works:

1. The Body (Compaction Container)

- Design: The garbage compaction truck has a large, sealed container where the waste is stored. The container is typically made of durable steel to withstand the pressure during the compaction process.

- Seals: The container is equipped with seals to prevent leaks and odors from escaping while the garbage is being compressed.

2. Loading Mechanism

- Manual or Automated Loading: In some cases, garbage is loaded manually, but many modern compaction trucks are equipped with automated arms or lifters that can pick up trash bins or containers, dump the waste into the truck's container, and then return the bin to its original position.

- Roll-on/Roll-off (RoRo) Loading: Some models use a system where the garbage is loaded onto the truck by rolling it into the compaction chamber. This is typically used for larger containers or in specialized settings.

3. Compaction System

- Hydraulic Ram: The heart of the compaction system is a powerful hydraulic ram or compaction blade. Once the garbage is inside the compaction container, the ram or blade pushes the waste into the container with immense force, compressing it to reduce volume.

- Ram or Plunger: The system may use a plunger or a moving wall (often called a "compactor blade") that moves back and forth to crush the garbage. This process significantly reduces the space required for the waste, allowing the truck to carry more.

- Hydraulic Pressure: The hydraulic system generates the pressure needed to compress the garbage. The hydraulic pump and cylinders are powered by the truck's engine or an independent hydraulic power unit. The system pushes the compaction blade against the trash, compacting it tightly against the rear of the container.

4. Dumping and Emptying the Truck

- Tilting Mechanism: When the truck reaches a landfill or waste disposal site, the entire container can be tilted to dump the compressed waste. This is often done using a hydraulic lift system that tilts the body of the truck, allowing the trash to slide out.

- Compaction Blade Positioning: The compaction blade may also be used to help push the compacted waste out of the container during unloading.

5. Compaction Cycle

- Load and Compact: The truck repeatedly loads waste into the container, compresses it with the hydraulic ram, and then moves the compressed waste to the rear of the container.

- Monitoring and Control: The driver typically operates the compaction system from the truck's cab, where they can monitor and control the operation of the hydraulic system, adjusting the pressure and movement to optimize compaction.

6. Safety Features

- Weight Sensors: Many garbage trucks have weight sensors to monitor the load and avoid overloading the truck.

- Pressure Relief Systems: To prevent damage to the truck or hydraulic components, the system may include pressure relief valves that prevent the compaction mechanism from being overloaded.

- Sealed System: The compaction system is typically fully enclosed to reduce odors and prevent waste from spilling out during transportation.

7. Types of Garbage Compaction Trucks

- Rear Loader: Rear-loading trucks are more common in residential garbage collection. Waste is loaded into the back of the truck, and the compaction system compresses it as it moves toward the rear.

8. Benefits of a Garbage Compression Truck

- Increased Capacity: By compressing the garbage, these trucks can carry much more waste than a regular non-compacting truck.

- Reduced Environmental Impact: With more waste per load, fewer trips are needed to the landfill, reducing fuel consumption and emissions.

- Cleaner Operation: The sealed compaction container reduces the risk of spills and leaks, keeping the environment cleaner.

Key Components of a Garbage Compression Truck:

- Hydraulic pump and cylinders to generate power for the compaction system.

- Compaction blade or ram that pushes and compresses the garbage.

- Waste storage container with seals to contain waste.

- Automated lifting or loading arm for emptying bins into the truck.

- Control system to operate the compaction and lifting mechanisms.

By utilizing the hydraulic power and compaction blades, the garbage compression truck efficiently manages large volumes of waste, making it a vital tool for waste collection and disposal in urban and industrial areas.